Negative Camber Explained

We get seriously nerdy about all aspects of negative camber. Want to setup your car for optimum handling? Want the slammed look with a compliant ride? Read on!

Jump To Section

Introduction suspension setup

Front-end alignment is often greatly misunderstood. The phenomenon determines how a car’s front wheels are positioned with respect to the road and the rest of the car. The front tire alignment of a vehicle directly determines how the front end tracks and affects overall tire wear.

The idea of a front-end toe refers to caster and camber adjustments that may be made. Generally, camber adjustment is the one that has the biggest impact on total tire wear. During a front-end alignment, a vehicle’s camber is normally examined and changed as necessary.

Both excessively positive and extremely negative camber may quickly wear out a car’s tires and have a detrimental effect on how the car handles. Car enthusiasts that are looking to run wide aftermarket wheels will often need to use negative camber to “tuck” the top of the tire inside the fender.

Design Requirements

Negative camber is incorporated into suspension components to optimize one of the front wheels during fast turns. Nearly all sports vehicles have their front wheels adjusted with a specific degree of static negative camber.

Determining how much negative camber a car should have is frequently challenging. The amount of negative camber present when the car is at rest, and with the two front wheels in the straight-ahead position is known as static camber.

For specific circumstances, sports cars and other high-performance vehicles frequently have significant static negative camber, such as 4-5 degrees. The wheel on the outside of the turn is the front wheel in question.

This wheel has a heavy load in this condition, and the suspension’s prebuilt camber settings ensure that even with a very tiny amount of steering lock provided, the front wheel will have an appropriate level of negative camber, providing the tire with excellent support and traction.

Again, this configuration should not be regarded as acceptable for most sports car applications and is more appropriate for vehicles employed in specialized performance driving applications. Sports vehicles typically require between 0.5 to 1 degree of static negative camber on the front wheels.

This could need to be raised to 1.5 degrees in some situations. As a general guideline, think of the great majority of sports vehicles for road or racing use as needing 1 degree of static negative camber.

During heavy cornering, I have seen some really appalling instances of factory sports cars that were configured with 1 degree of negative static camber but display up to 5-7 degrees of positive camber on the front wheel.

These vehicles nearly never have enough caster, and their suspension design does nothing to encourage a decrease in negative dynamic camber. Such vehicles only exhibit this behavior when subjected to extremely intense cornering forces, which is typically an uncommon event for a production sportscar.

Static camber refers to the angle between the vertical axis and the wheels when viewed from the front of the vehicle, with the wheels in a static or non-moving state. A positive camber angle means the wheels are tilted outwards, while a negative camber angle means they are tilted inwards, as in stanced drift cars.

Dynamic camber, on the other hand, refers to the change in camber angle that occurs as the wheels move up and down as the vehicle goes over bumps or uneven surfaces. In this scenario, the camber angle changes dynamically and affects the vehicle’s handling and stability.

In summary, static camber is a measure of the angle of the wheels at rest, while dynamic camber is the change in angle as the wheels move during driving.

The two front wheels should be vertical to 1 degree of negative camber and without any toe-in or toe-out during intense straight-line braking. This is an undeniable truth in the strictest sense. Although this ideal is rarely achieved for several reasons, the criteria is sound.

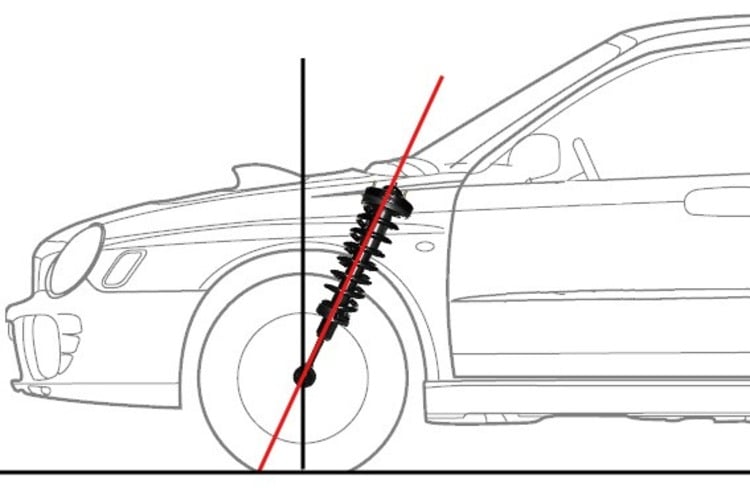

Caster Explained

This is the angle at which the rotating axes of the front wheels are inclined in the vertical plane. As the front wheels are rotated left or right from the straight-ahead position, caster causes camber to vary.

In a perfect world, the front wheel on the outside of the turn would tend to accrue negative camber, preventing it from going positive or, if it did, limiting it to a maximum of 1 degree. The front wheel within the turn should ideally retain a camber of roughly 1 degree negative and not start to gain much camber.

Gaining more negative camber than 4-5 degrees will almost always be excessive and cause the inside edge of the tire to show excessive wear. Even though zero camber is the preferred ideal, it is okay for the front wheel on the outside of a turn or curve to go positive by up to 1-1.5 degrees.

Even though it may appear to go against all the standard advice, doing so might be advantageous if it allows you to get maximum tire grip with even tread wear.

Maximum tire grip is the primary necessity for racing, then ensuring the longest possible tire life. This often entails sacrificing optimal tire wear to get maximum tire grip. Set the tires for the best service life if the grip holds. Although it’s uncommon for this to happen most of the time, the front wheel on the inside might possibly move somewhat in the positive direction.

On the inside of the turn, the front wheel’s geometry should be as perfect as possible. Years ago, when tires were not as broad and had to wear uniformly across the tread while also providing maximum grip, the fundamentals of both front wheels being somewhat positive during high-speed turns were established.

Although perhaps not necessary for all racing scenarios, both front wheels should be adjusted with an identical amount of caster for almost all road vehicles. There are times when one side might have one to two degrees caster than the other for racing purposes.

Depending on specific races, there may be more high-speed turns in one way than the other, all of which are made at lesser speeds when the geometry in that direction isn’t as important.

The wheel on the outside of a turn will tend to gain negative camber, and the wheel on the inside of a turn will tend to gain positive camber, or, that wheel is more likely to remain near vertical and not gain negative camber in a turn, the greater the caster angle built into the suspension geometry.

To enhance the performance while cornering, the amount of caster can be raised or lowered. It doesn’t take much caster to induce even more negative camber in a car that already has a lot of static negative camber.

The wheel on the outside of the turn will have quite a negative lean on it if there is 2-3 degrees of static negative camber and 7-8 degrees of caster. If there is a lot of steering lock applied, the wheel on the inside of the turn might go positive.

It is important to keep in mind that when racing, very little steering lock is needed. High-speed sweeping corners, for instance, sometimes only require a little portion of steering wheel turns to be effectively navigated. The steering wheel may only be rotated a quarter turn, or the angle of the front wheel may only change by 2-3 degrees from straight ahead.

Although it is sometimes the most crucial need for suspension setup, this aspect is almost never considered. As well as straight line speed, a car needs to be able to maneuver around the quickest sections of a course with ease.

In contrast, slow bends don’t need such exact suspension settings, albeit they still must be very accurate. Without the automobile being ideally configured for it, it is impossible to navigate a high-speed sweeping turn at the fastest possible speed. Only when it is difficult to adjust the caster to generate enough dynamic negative camber during difficult cornering is a lot of static negative camber often employed.

The outer edge of the tire tread seldom shows wear when a car has too much negative camber for cornering, and it doesn’t show as much wear as the inner side of the tread does. The treads on both tires show virtually identical wear, which is an indication that the tires don’t wear down equally.

Understeer may be caused by suspension settings, including spring rates that provide excessive dynamic negative camber; however, this effect is less noticeable on long, sweeping turns. Of course, each automobile is unique, therefore small tweaks must be made for each one to guarantee that the suspension design produces the greatest handling characteristics for each car.

Consider the typical range of caster to be between 3-6, with the basic setting’s possible expansion range being up to 7 or 8. 4 or 5 degrees should be the first setting. Increase the caster if, during a hard corner, the front wheel on the outside of the turn exhibits gross positive camber. On a low-slung sports vehicle, it’s doubtful that more than 7-8 degrees would ever be required.

Although it will hardly ever be adequate, 2 degrees of caster should be considered the least quantity that could ever be applied. 3-6 degrees on average are likely to be utilized, with more seldom being required. For certain situations, cars have employed up to 15 degrees of caster, but never more.

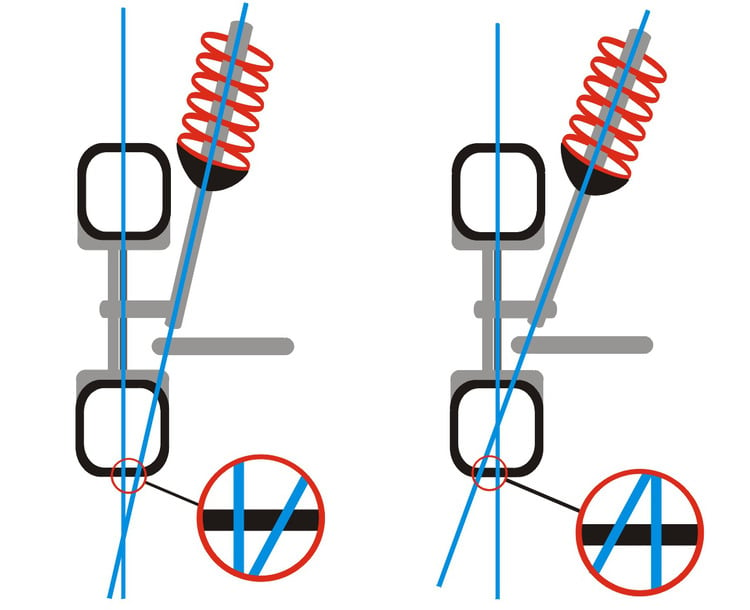

Kingpin Inclination

Although kingpins are no longer a common feature of automobiles, the kingpin’s role in steering geometry is still important. The axis of a line connecting the top and bottom ball joint centers of the stub axle supporting the wheel is called the kingpin inclination.

The link between this point and the tread of the tire is crucial. The line connecting the top and bottom ball joints, or rose joints for that matter, is projected to the ground.

Typically, a location inside the tread region of the tire serves as the point of kip contact with the road. However, when wheels are installed with offsets that are different from the originals, the wheel rim is shifted outward in respect to the hub, and the situation might change drastically, producing less-than-ideal outcomes.

Consider that the ideal range for KPI is between 9 and 12 degrees, with 10 degrees being typical. Although the effective angle of the stub axle may be changed by slightly modifying the negative camber of the wheel, there is a limit to this. Normally, it is not feasible to change the kpi of the stub axle. These angles are predetermined while creating stub axles.

Wheels with a lot of insects are common in the production of saloon automobiles. It is a well-established idea to use inset wheels such that the ground contact area of the kpi line is inside the contact patch of the tire tread. Wheels with a lot of offsets are sometimes used on sports cars and kit cars only for aesthetic purposes, however, this frequently compromises handling.

Within the parameters of a sound design, having a broad track is great, but not at the price of sound geometry. In general, ‘inset’ wheels on the front of a car perform better than ‘offset’ wheels.

For instance, vehicles with inset wheel rims that have afterward acquired heavily offset wheels and maybe spacers may have wheels that are now 3 inches further from the hub than they were before. The track will be 6 inches wider, but the steering will still tend to kick back a lot, especially over ridges and bumps. This leads to a loss of control and is not a desirable scenario.

Disadvantages

Numerous sports vehicles with significant negative camber, such as 2-3 degrees, don’t have decent handling and quickly degrade the inner edges of the tire treads. When applying a decent amount of steering lock, these automobiles frequently understeer.

The cause of this is that the front wheels have excessive negative camber, which causes the most heavily laden tire’s tire patch to shrink the more the steering wheel is twisted. On extremely light sports vehicles with very wide tires, this effect is especially noticeable.

When provoked, they will severely understeer, with the front tire on the outside of the turn seeming to be about to come off the rim. Let’s just say that, with a little geometry tweaking, the identical car could be made to handle superbly and not display excessive positive camber in the same circumstance.

Therefore, it is crucial to support the heavily laden tire on the outside of a turn. Take a sportscar and brake aggressively in addition to this. The suspension geometry nearly always results in increased negative camber when the front of the car dips.

Therefore, the tires are oriented to the road surface exactly when the greatest feasible tire patch in full contact with the road is needed for stopping.

Conclusion

To ensure that an automobile is largely free from evident suspension or steering problems, there are several things to examine. In far too many cases, it will be quite easy to fix the issues that a stock or badly modified automobile displays.

The size and design of each car’s suspension system make tiny variations in how well each car reacts to the same variables, such as caster, negative camber, zero toe, toe-out, and the contact area between the tire and the road or track surface.

Good handling is all about the weights operating on the wheels and the attitude of the wheels in various dynamic circumstances. In most cases, it takes a lot of effort to check and adjust a sportscar’s handling. A sportscar will most surely only give you what you put into it.