Spring Rate Conversion Made Simple

Don’t let spring rate calculations coil your brain up! We’re breaking down and simplifying everything you need to know when it comes to converting.

Jump To Section

Springs support the weight of the vehicle and also absorb road shocks. Our coilover guide explains this in detail – simply put, without springs, the entire car would jerk when in reality, only the wheel bounces up and down when passing over road bumps.

There are four types of springs used in the automotive industry. Coiled springs are much more common, but leaf springs, torsion bars, and air springs are also used throughout the industry.

We talked about the springs bearing the weight of the vehicle. The four springs on each strut are the most crucial aspect of the chassis design.

If you’re going for a race build, the maximum speed a car attains while turning will affect lap times the most.

For those of you that aren’t sure whether softer or harder springs are going to be better suited for your needs, we recommend checking out this video:

The spring rates and roll centers are responsible for the car’s behavior while taking a turn, and there are a lot of vehicle dynamics surrounding this.

How To Calculate Spring Rate

There are several things you should know about springs.

Firstly, you need to know exactly what the spring rate is for a particular spring. This is not as simple as reading the stamped numbers on the spring – however, this can be a good place to start.

Manufacturer’s sometimes make mistakes and may overrate, or, underrate springs. The spring rate may also be subject to change if the springs have been used heavily, so take care while purchasing a used set of coilovers or springs for your car.

It’s common to mix up spring load with spring rate and hence it is critical to understand the distinction in order to fully comprehend how your suspension functions.

The spring load, which is measured in lbs, is the force required to compress the spring to a specific height.

The spring rate, which is measured in pounds-per-in, is the force required to compress a spring one inch.

Assume a car has an equal weight distribution and weighs 4000 lbs. It would then weigh 1000 lbs. at each wheel as a result. The sprung weight at each wheel would be 800 lbs. if we assumed an unsprung weight of 200 lbs.

Unsprung weight refers to the weight of the tire, wheel, wheel knuckles, hub, and one-half of the spring as well as the shock and control arms, which are components of the car that are not supported by the springs.

The body, frame, engine, transmission, as well as half of the spring, shock, and control arms make up the sprung weight.

For spring rate calculations, you only need to only consider the sprung weight, since this is the weight that is acting on the spring.

Wheel rate, on the other hand, is something that combines both the unsprung and sprung weight, and takes into consideration the position and angle of the spring as well.

Coiled spring rates are calculated by using the following formula, assuming that you know what material your spring is made of. A quick google search will reveal the torsional modulus of your springs material which is a unit value,

Spring Rate = Gd4/8ND3

Where G is the torsional modulus (in psi), d is the coil thickness (in inches), N is the number of coils, and D is the mean diameter of the spring (in inches). If you have a progressive spring, this formula will only give you an average value, and not the actual one.

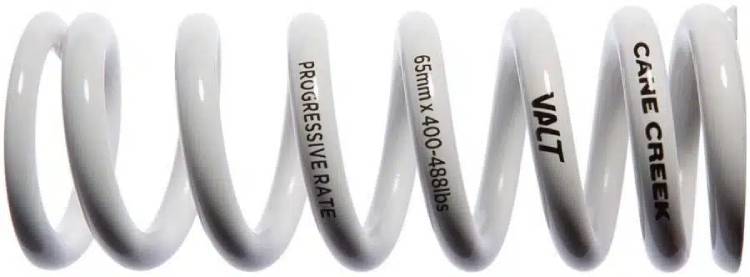

A progressive spring is one in which the diameter of the spring reduces, or the coils get more concentrated as you go along the length of the spring.

The idea behind progressive springs is that it has different spring rates for different sections of the spring.

If you’re planning to upgrade to a suspension system that uses progressive springs, or if your car already came with them, you can use the same formula to calculate the spring rate.

Spring Rate Conversion Chart

Different manufacturers use different units for spring rates. This is why a spring rate conversion table or spring rate calculator is commonly required to convert between pounds per inch (lb/in) and kilograms per millimeter (kg/mm).

All you need to know to convert kg/mm to lb/in or vice versa is that 1 kg/mm = 56 lb/in. Spring rates, in essence, characterize how stiff or flexible spring is as we’ve already discussed. This has a lot of effect on the handling, but we’ll give you an example of this.

Spring rates allow you to change your handling by specifying a stronger or softer spring rate in the front or back to fine-tune your balance.

Take a look at the Mazda MX-5, which is a perfect example of how well cars handle when they are perfectly balanced. We have a full guide on coilover sets for the MX-5 if you’re interested.

Different brands may have different shock settings, which change how the spring rates affect the ride and handling. Most aftermarket brands selling coilovers will have two-way adjustment, or even three-way adjustment, allowing you to change the spring rate.

We always recommend discussing your unique objectives for your vehicle with a knowledgeable tuner, who can also aid you in determining what spring rates you require. Refer to the conversion chart below to better comprehend coilover and lowering spring options to suit your needs:

| 16 kg/mm | 896 lb/in |

|---|---|

| 15 kg/mm | 840 lb/in |

| 14 kg/mm | 784 lb/in |

| 13 kg/mm | 728 lb/in |

| 12 kg/mm | 672 lb/in |

| 11 kg/mm | 616 lb/in |

| 10 kg/mm | 560 lb/in |

| 9.0 kg/mm | 504 lb/in |

As an example, you can read our guide on finding suitable coilovers for your Nissan 350Z.

What Spring Rate Should I Get?

Make a list of the brands you’re considering within your pricing range, including their spring costs and other qualities. Then compare their spring rates to see which are normally stiffer or softer, which affects handling and ride.

The process essential to choose the proper rate, and why it’s necessary, won’t make any sense at all unless the role of a spring in relation to total suspension dynamics is made apparent.

When the wheels rise and fall over road surface imperfections, the springs temporarily operate as energy storage devices, considerably reducing the magnitude of impact loads transferred to the chassis by the suspension system.

As a result, a soft or low-rated spring that allows for considerable deflection under moderate loading will decrease the impact of the forces conveyed to the vehicle occupants to a minimum. The spring rate is in fact, equal to the load per unit of deflection.

We already told you that coiled springs are divided into two types: linear rate and variable rate. Linear-rate coil springs feature equal coil spacing and a single basic form with a constant wire diameter.

When the load on a linear-rate spring is increased, the spring compresses and the coils twist or deflect. The coils unwind or flex back to their original position once the load is released from the spring.

The spring rate is the amount of force required to bend the spring one inch. Linear-rate coil springs have a consistent spring rate no matter what the load is. For example, 200 pounds will deflect the spring 1 inch, whereas 400 pounds will deflect the spring 2 inches.

Variable-rate coil springs come in a range of wire diameters and shapes. The most typical variable-rate coil springs feature a uniform wire diameter, a cylindrical shape, and unequally spaced coils.

When the wheel encounters a road irregularity, the inactive coils (coils that are spaced closer) at the spring’s end provide force to the spring. When the transitional coils (coils that are spaced further) are squeezed to their maximum load-carrying capability, they become inactive.

The active coils are active across the whole range of spring loading. When a fixed load is supplied to a variable-rate coil spring, the inactive coils theoretically support the load.

When the load is raised, the transitional coils sustain the load until they reach their full load-carrying capability, and the active coils handle the remaining overload. Pretty cool, huh?

As an illustration. If you had a car with 700 lbs.-in. front springs and a roll angle of 2 degrees and wanted to lower the roll angle by 1 degree, you’d need to add 1400 lbs.-in. front springs.

This would effectively double the roll resistance. However, boosting the spring rates this much would disrupt the ride and cause the car to understeer.

Getting back to the point with what spring rate should you go with – the answer is something that is not very pleasing! Spring rates are calculated pretty intricately for each and every car, so we advise you to stick close to the original or OEM valve springs.

Increasing the spring rates reduces the roll angle. Unfortunately, increasing the spring rates might alter other aspects of the vehicle’s handling.

If you stray too far from the OEM value of the spring rate, you’ll end up with something that will also be too stiff or too bouncy to drive, and you’ll have wasted your money at the same time.

What Is A Good Spring Rate?

Although a greater spring rate lessens body roll, the ride becomes harsher.

A softer spring will enhance ride quality while also allowing the tires to follow uneven road surfaces for increased grip. Too stiff of spring will prevent a tire from producing any grip at all if it briefly loses touch with the road.

If you’re wondering what lowering springs are and what they do, we’ve got you covered.

Why is there such a fuss over choosing the ideal set of springs for your car since the function of the springs is so straightforward?

It all boils down to ensuring that the shocks can move within their appropriate range of motion and understanding how crucial the shocks are to the overall performance of the handling system.

The tires are the only component that has a greater impact on handling than the shocks. Shocks regulate the pace of weight transfer in a corner by slowing the action of the spring.

The key to good handling is maximizing the rate of weight transfer, and the shocks regulate how the entire suspension performs.

Shocks have a relatively small range of motion, and as they approach their extremes of travel, their performance quickly declines. Proper spring selection is crucial since it depends on the springs to keep the shocks operating in their ideal range.

The shocks will be forced out of their ideal operating range if your automobile sits too high or too low as a result of having the wrong springs, and they won’t ever work effectively.

People frequently believe that there is a problem with their shocks, however, in 80% of cases, apparent shock issues are caused by improper spring installation. So how could you correct this?

Consider this: to balance out the upward and downward forces with a sprung weight of 1000 lbs. at each wheel, you’d need a spring load of 1000 lbs. to keep the car at standard ride height.

If the prior wheel travel was 5.00 inches up and 5.00 inches down, the wheel spring rate would need to be 200 lbs. per inch to absorb a 1.00 g bump. A 1g bump is equivalent to most road imperfections and is calculated using gravitational forces acting on the car.

This spring rate would cater to complete suspension travel; however, will be considered soft by most people. There are several circumstances that will require the use of higher-rate springs in high-performance applications.

Even in our scenario, the spring rate only just accounts for the wheel travel, and it is a general practice to add 2 inches to wheel travel when calculating spring rate so that you’re safe from tires rubbing against fenders.

Conclusion

The softer the springs, the smoother the ride; the stiffer the springs, the harder the ride. As long as the elasticity threshold is not surpassed, the spring rate is largely determined by Hooke’s law.

We advise you to also check out our guide on coilovers for a better understanding.

Spring Rate Conversion FAQ

In this section, we’ll cover the frequently asked questions when it comes to spring rate conversion.

- What are the units for spring rate?

Spring rates are measured in kilograms per millimeter (kg/mm) as well as pounds per inch (lb/in)

- Is a higher spring rate better?

That totally depends on how you want your car to feel, stiffer rides have stiffer springs, and softer, smoother rides have softer springs. Both have their advantages and disadvantages.

- What is spring rate used for?

Spring rates are used when upgrading your car’s coilovers, or you could even need a value for spring rate when changing springs.

- What is the unit of spring rate?

Kg/mm, and lb/in are both used as units of spring rate.