Turbo Flutter – Your Questions Answered

We love turbos, and we’re crazy about the sounds they make. But sometimes, the sounds from your turbo may be a sign of issues, and we’re here to explain why.

If you’ve done your homework on engines you probably know all about them. But we’re here to tell you about turbos and turbocharging and what makes those sweet whistle noises we all love here at Drifted.

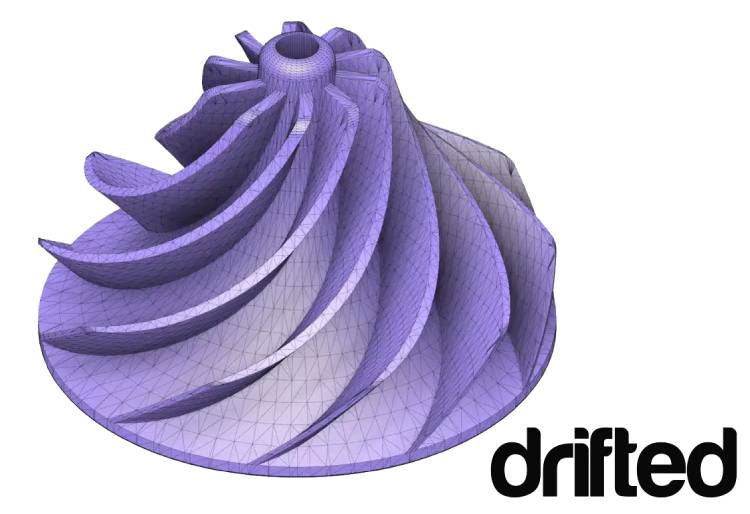

Turbos sit in the heart of petrolheads and are a must-have for car enthusiasts of all sorts. A normal turbo would look something like this if you’re seeing it for the first time:

Connected to the engine are the vehicle’s intake and exhaust manifolds, which are each responsible for getting air into the engine for combustion to happen, and getting exhaust gases out.

The turbo is responsible for forced induction; hint: Superchargers also do this, interested to know how the two compare? Make sure you check out our turbocharger vs supercharger guide.

Turbos are directly connected to the exhaust manifold. Turbos use the exhaust flow pressure to spin a centrifugal impeller, or a turbine wheel, in a vacuum housing, to create high-pressure air.

Turbos have two impellers; one spins with the exhaust gases (the ‘hot side’) and causes another impeller connected to the same shaft to spin as well. This is the ‘cold side’ of the turbo. An impeller is designed in such a way that its blades ‘grab’ onto air.

The cold side of the turbo takes fresh air in; compresses it, cools it, and force-feeds it back to the engine via the intake manifold. This is the turbo inlet.

A throttle body is connected between the intake and the engine, which opens and closes to allow or restrict the amount of air according to how much you’ve pressed down on the accelerator.

Cooling increases air density as well, so you have a richer air-fuel mixture inside your pistons. Getting more fuel in an engine is not difficult, but getting more air in is always difficult!

What Is Turbo Flutter?

To understand turbo flutter best, let’s consider a scenario where you’ve floored the accelerator, but you see a turn ahead. So you instinctively let go of the accelerator. Your car does have a turbo installed, and these turbos are spinning at very high revs.

By very high revs, we mean in the eighty thousand to two hundred thousand revolutions per minute. This is why turbos sound the way they do when they spool up.

Turbos usually spin at forty thousand RPMs on idle, but with the accelerator pressed fully, the engine is working much harder and produces much more exhaust, which drives the turbo harder and at higher RPMs.

This is also how you get more power when you press the accelerator and is also a base for tuning throttle response. We won’t go into modifications that alter your throttle response, but it is doable.

Now consider this situation: You’ve let go of the gas, probably because you’ve run out of straight roads, and this closes the throttle body. Closing the throttle body means that there is now a restriction in the intake manifold.

Remember that the turbo is still spinning, and still trying to compress more and more air to feed to the engine. The sudden restriction means that the compressed air has no place to go, and the only direction it can go is back to the turbo.

When this happens, the airflow going back towards the turbo collides with the impeller blades, in an attempt to reduce the impeller’s momentum. This produces a very characteristic fluttering sound with a lot of noise, also called a compressor surge.

Do All Turbos Flutter?

Pressure builds up in the downpipes and headers of the exhaust system because there is no outlet for the exhaust gases. With that being said, not all turbos flutter, and this is due to innovative engineering.

Check out our guide on the best turbo kits for the Honda K24, a pure VTEC engine with an added factor of reliability.

Engineers when designing the turbo, also devised a solution for the excess pressure build-up. They used a blow-off valve, which has a firm spring that does not compress under normal air pressure inside the downpipes.

However, once the backpressure exceeds in the pipelines, the spring compresses, opening an outlet from where air escapes. You might’ve heard a hissing noise in turbo engines when you let go of the throttle. This is the blow-off valve at work.

With a BOV introduced into the system, excess air will not go back to the turbo. Hence, the turbo will not flutter. Otherwise, without the BOV, the turbo will definitely flutter when you let go of the throttle after hitting it fully.

Is Turbo Flutter Bad?

The truth is that turbo flutter doesn’t do any good, even if some tuners say that the sound turbo flutter makes is music to their ears.

A turbo is pretty expensive to install in the first place. You’ll be looking at $5-6,000 in parts and labor. Secondly, turbos are not designed to flutter, and only compress air in one direction. Turbo flutter causes a lot of back pressure to go through your turbo, which puts a lot of strain on it.

Your turbocharger internals are at risk as a result of this stress because the manufacturer did not take turbo flutter into account, and you’ll be introducing more stress to a component that is already under high thermal and mechanical loads.

Now, the top turbo manufacturers like Garrett, Honeywell, Cummins, etc. will manufacture turbos with higher strength ratings, and they just might be able to handle turbo flutter. Turbo kits off of eBay will definitely not, so be sure to add a BOV in them.

You might also want to include a turbo timer. Confused? We’ve got you covered, with our full guide on turbo timers, and what they do.

With that being said, turbo flutter is bad for a turbocharger’s performance and significantly reduces a turbo’s lifespan. With all the back pressure acting on the turbo, the turbo slows down. This means that the next time you hit the gas, it will take more time to get the turbo spinning in the right direction again.

How To Create Turbo Flutter

There are two things you could do, whether you prevent turbo flutter to preserve the expensive turbocharger, or you simply want to hear the distinctive fluttering noises that have got the internet going crazy. I see a lot of turbo flutter videos on Instagram myself.

The main step in achieving this is to remove the blow-off valve. No mechanic will advise this, but once again, if you have small, low-pressure turbos, with low boost levels, we’d say go for it. You will definitely have a chance against the turbo going bad.

An absence of a blow-off valve, and sealing the opening where it was will create backpressure. This will make the turbo flutter.

A final word of warning though, you might damage your exhaust system as well, and it will be more prone to leaks and premature wear. You’ll also be increasing engine load and reducing reliability in the long run.

How To Stop Turbo Flutter

A vast majority of people have a good sense that flutter is bad, however, it does somewhat boil down to personal preference and whether or not they enjoy the sound. By installing a blow-off valve, which almost all turbocharged cars have, flutter can be eliminated.

The role of a blow-off valve is to open a different outlet, which has been discussed above as well. Selecting the proper type of BOV is critical at this stage for all aftermarket turbocharged setups. Usually, all aftermarket BOV have a method to adjust the softness or hardness of the spring.

There are rubber diaphragms connected to the spring that close and open accordingly. Modern turbochargers and turbocharged engines come with a blow-off valve that’s already tuned, so as to stop the turbo from fluttering. You need not worry about these.

Difference Between A Wastegate And Blow-off Valve

Although wastegates and blow-off valves are both components you pair with turbochargers, they serve very different purposes. Many people will confuse one for the other, we’re going to clarify this confusion.

In order to prevent turbo-flutter, blow-off valves are available, as we already explained. They are typically closed and are located on the engine’s intake side.

A BOV (shown below) opens up and lets pressure escape when it senses an excessive amount of pressure in the intake of the engine past the turbo. BOVs may either release this into the surroundings (vent-to-atmosphere bovs) or channel it towards the exhaust of the car.

External wastegates (also shown below) are located on the engine’s exhaust side right before the turbo, keeping the turbo from producing an excessive amount of boost. If the turbo is generating a higher level of boost, some amount of exhaust gas will be released through the wastegate, keeping the turbo from spooling too much.

An understanding distinction between the two lies in where and why the pressure is diverted. We’re going to discuss this, but it is relatively simple to understand.

Both wastegates and blow-off valves are used in situations where you want to vent exhaust. Wastegates are made to withstand higher thermal stresses since they are connected to the much hotter exhaust manifold.

A turbo blanket may also be used in situations where you want to reduce temperatures within your engine bay, solely because of the high heat which a turbo produces. This would definitely help both your pipings and other components live longer.

Blow-off valves on the other hand are positioned on the boost side of the turbo, after the intercooler, and are used to release excess boost once you release the gas pedal.

You need to remember that as exhaust air travels to the turbine housing as an engine revs up, the turbo spins too. More exhaust pressure means more boost. Most of the time, the full amount of turbo boost is not required, which is why wastegates are in place at the turbocharger inlet.

The wastegate also has springs in place, that are finely tuned for a particular value of pressure, which is usually measured in psi. These springs exert a downward force on a valve which leads to an opening. Springs in the wastegate can be set according to how much boost is required to completely open the valve, just like in a BOV.

Wastegates can also be electronically operated. In this case, their application becomes more finely tuned, and the wastegate can be connected to the ECU, which will be responsible for controlling its opening and closing.

Similarly, blow-off valves can also be electronically controlled, and with both components being controlled by the ECU, tuning becomes easier and more precise. Precise tuning will consequently result in better performance. A win-win situation we might say!

Conclusion

We’ve done our best to make sure you know the ins and outs of turbo flutter, how it’s caused, and how you might prevent it. We at Drifted think turbo flutter is actually bad for business, so you should definitely avoid it.

We’ve also told you about electronically controlled blow-off valves and wastegates. These are the way to go if you want precise tuning, and you’re looking for peak performance. The small things do matter, and electronically controlled components will behave much better than manual ones.

We understand you might have some additional questions regarding turbo flutter. We’ve created a short FAQ section on some common questions that we know you might be asking.

Frequently Asked Turbo Flutter Questions

Here are some of the commonly asked questions about turbo flutter.

Can you get turbo flutter on a diesel?

Yes, turbos on a diesel function the same way as they do on a petrol engine. Wastegates and BOVs are found on diesel turbo engines as well.

How do you get a turbo flutter on diesel?

In the same way as you would get on a petrol engine, by removing the blow-off valve.

Why does my turbo flutter, but I have no power?

This is a sign that your turbo might be damaged. If you’re not creating any boost, and you did not have a BOV in place before, your turbo is probably at fault. A good reason why you should always run a BOV in a turbo setup, especially when making large amounts of boost.

Is turbo flutter illegal?

No, but it could be costly.

How much boost do you need to run without a BOV to get turbo flutter?

This isn’t a question you should be asking, fluttering occurs at high turbo RPMs, so even with low boost pressure and full throttle, you might notice flutter when you let go of the gas pedal.

What’s better for a turbo, a blow-off valve, or just blanked so you get turbo flutter?

Definitely a blow-off valve! Fluttering should be avoided at all costs, otherwise, the turbo might fail before its usual life.

(4 votes, average: 4.50 out of 5)

(4 votes, average: 4.50 out of 5)